3D printers will play a key role in Industry 4.0.

By Henry Brown

The first industrial revolution was a game changer. Economic historians say it started around 1784 with the invention of the first mechanical loom. Later came the steam engine and a whole host of other technologies that replaced labor. All of a sudden, factories started popping up, and each worker could produce more than ever before. The next stage in industrialization came with the emergence of mass production and the division of labor. Workers were assigned to a particular task and stuck with it, gaining massive proficiency in the process. Then along came the third industrial revolution – the one most of us have lived through. This revolution was all about using IT and software systems to automate production and remove the labor element. As a result, employment in manufacturing has declined from around a third of the workforce to just ten percent today.

But that’s not the end of the story. Today we’re on the eve of the fourth industrial revolution. And this one looks set to eclipse all those that have gone before. This next industrial revolution will be characterized by the use of big data, smart machines and intelligent systems. Everything will be connected. And everything will react, in real time, to disruptions elsewhere in the system. It’s a huge opportunity for those small businesses that can get in early.

Collect and manage data

Perhaps the biggest issue right now for manufacturers is the fact that they’re not collecting enough data. Data is the key to unlocking the potential from the fourth industrial revolution. It’s data that will be used to diagnose problems on the production line. It’s data that will drive higher integration with supply chains and markets. And it’s data that will ultimately be fed to factory robots to make them smart.

Right now there are solutions on the market, like Factbird by Blackbird. But too few small businesses are actually using these solutions to their advantage. Manufacturing is stuck in a bit of a rut and needs to start thinking more like a tech startup. The future of manufacturing isn’t going to be the same input-output model it has been since time immemorial. It’s going to be in the use of software platforms that facilitate bespoke products.

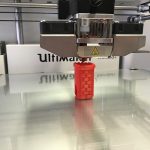

3D printing

Most manufacturers think that 3D printing is something that is only useful in the prototyping stage. But when the fourth industrial revolution kicks off, it’s going to hit the mainstream. By the time we hit the mid-2020s, experts predict that the resolution of 3D printing will be sub-micron. That means it will have a resolution sufficient to print out things like clothing. Data can then be fed to factories in real time from consumers regarding their height, weight, and dimensions. And factories can then use this data to output tailored products for their customers. Hence, it’s a move away from mass production and towards individually produced items.

Adapting business models

Governments have tried to drive the movement towards Industry 4.0. But it’s those small businesses that can successfully adapt their business models that will succeed. Small businesses need to increase the amount of customization they offer customers. They need to be ready to adapt to new technologies as they arise. And they have to be able to deliver industry 4.0 proof-of-concept to get investors on board.

____

Henry Brown is an online marketing executive. When he isn’t talking shop he’s roaming the streets of London, uncovering the extra-ordinary in the ordinary.