By Henry Brown

There is no denying the fact that 3D printing has become an extremely popular phenomenon over the past few years. From an impressive time to market to improved levels of quality, a lot of people are feeling the benefits of going down this route. Read on to discover more.

When it comes to 3D printing, there are many different ways that you can reduce your business expenditure. Before 3D printing, companies had to invest a significant degree in this area. It meant that prototyping inject molds and production runs were required, and they both cost a significant degree. Nevertheless, this is something you certainly do not need to fret about anymore, and this is because a 3D printing service is one that involves additive manufacturing, which means you can create the likes of parts and tools at a rate that is much cheaper than it would be if you were using traditional machinery.

Another way in which you will make savings is because 3D printing will reduce the potential for any accidents to occur. This is because it is now easy for you to test any of the ideas you may have, and to do so quickly. Cost savings can also arise from the fact that less human resource is required and you can also print numerous prototypes on demand too. This is pivotal because they more time you spend on this the more money you are going to be wasting

Of course, you are not simply advised to go for the cheapest 3D printing service you can find. You need to be sure that your cheap 3D printing items are going to be filled with quality and look impressive too. If you consider price and price alone, then this is certainly a recipe for disaster. Look for instant (LTL) freight shipping quotes so you can lower the cost of shipping too. After all, product costs need to be considered as a whole.

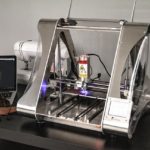

How FDM 3D printing works

FDM 3D printing is one option you have available when it comes to manufacturing products via the use of a 3D printer. Other options range from Stereolithography Apparatus (SLA) to Selective Laser Sintering (SLS).

From end-use parts, to functional prototypes, to concept models, FDM is ideal for a wide assortment of builds. So, let’s take a look at how this type of 3D printing works. The process is quite simple, as the thermoplastic filament is heated and extruded to build parts, layer by layer from the bottom up.

When you invest in an FDM 3D printing service, the process will always begin with pre-processing, which will involve using a program to slice and position the CAD file. It will also calculate a path to extrude the thermoplastic and any additional support material. Once this is done, the thermoplastic is then heated by the 3D printer until it is in a state that can be described as semi-liquid. After this, the liquid is deposited along the extrusion path in ultra-fine beads. The removable material is often deposited, acting as scaffolding, when buffering or support is required.

The final part of the process is post-processing when the support material is dissolved or broken away in a mix of water and detergent so that the part is ready to use. From making complex cavities and geometrics practical to easy use of technology, there are many benefits associated with this approach.

______

Henry Brown is an online marketing executive. When he isn’t talking shop, he’s roaming the streets of London, uncovering the extra-ordinary in the ordinary.